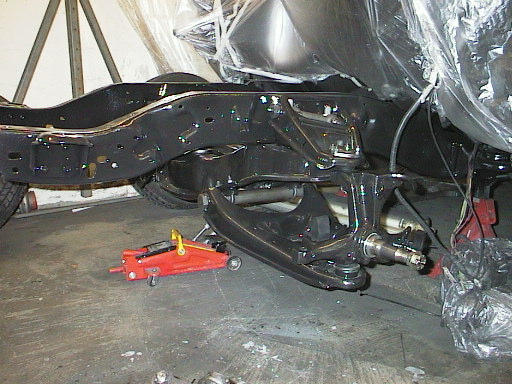

Summer 05Got rings installed to the pistons but break one oil ring from the #6, no worries, mailed to Tim and asked him to send one set of rings for me. So, all of them are in except the last one. Like some of you may remember ,the second ring is from Total Seal, nice to see how they work in street Cummins. Also got some of the front end components bolted back on, it's really nice to actually bolt something on, after tearing everything off and spreading them around the garage.

männan renkaat asennettu, yksi öljyrengas meni poikki (kuutos-sylkky), amerikan timppa lupasi lähettää uudet. Toinen rengas on Total Sealilta, saa nähdä kuinka toimivat katukäytössä. Osa etupään osista on pultattu paikalleen...

Summer vacation is almost over and got finally some "garage time" arranged. Sprayed more coatings, one paintable coating for entire chassis and frame, then top coating with black Temadur 90 to get a glossy and slippery surface in order to help keep the chassis clean. kesäloman rajoitukset alkaa olla ohi ja voi taas palata tallikauden kiehtovaan aikaan, lisä kerros maalia spreiattu runkoon ja alustaan, lopuksi pintaan liukas Temadur 90 pinta. June 05

Steel balls where used for inside of the valve covers because they get them clean but leave the surface smooth, for the outside I used aluminium oxide to get the surface coarse for painting. The brake calipers are done with the aluminium stuff.

Venakoppien putsaamisessa käytettiin teräs kuulia koska ne putsaa ja jättää pinnan tasaiseksi, ulkopuolella käytettiin alumiinioksidia

valve cover

brake calipersRods shot peened, I used piece of rubber hose to protect the upper end bearing and old bearings for lower end protection.Kiertokanget kuulapuhallettu, laakerin pinnat suojattu kumiletkulla puhalluksen aikana.

May 05

Active weekend; blew head gasket from the daily truck, replaced it, shot peened the rods, paint the frame, and made a "raku-kiln"...Vauhtiviikonloppu; kannen tiiviste pamahti pikapista, työntötangot kuulapuhallettu, runko maalattu ja raku-uuni väsätty...

Frame is now zinc coated twice, then primed and top coated ones. I'm going to spray another layer of top coating for it today. Runko sinkkimaalattu, vielä pohjamaalit ja kiiltävä maali parina kerroksena

Finished frame with shiny paintCleaning of the frame ongoing.Rungon putsausta...KOKO runko puhtaaksi!

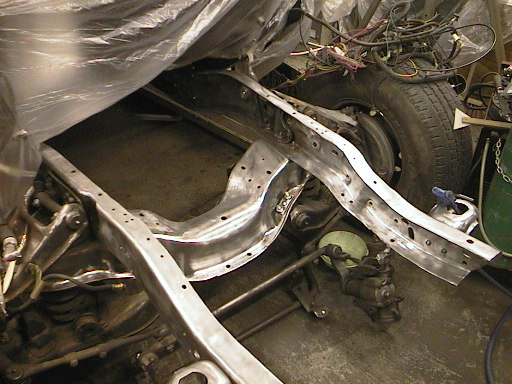

Front part of the frame is painted and I sand blasted rest of the stuff, prior painting, they too have same coatings than the frame, first zinc, then primer and black for the top.Lähtee pikkuhiljaa mopo käsistä, pientä askartelua rungon osien kanssa...mihin vetäisi rajan?

April 05

Got front part of the frame painted with zinc paint and today after work going to pick up primer (Temacoat GPL-S Primer) which is next layer and for top coating (Temadur 90). Here's links for the data sheets of primer and top coating. PL-s+primer.pdf and Temadur+90.pdf Runko maalattu sinkkimaalilla, linkeissä lisätietoa maalista

I took off everything to make the cleaning easier, now I could sand blast the smaller parts prior painting and replace lower arm bushings too. koneen runkoaisojen siivousta, tarkoitus hiekkapuhaltaa pienemmät osat ja vaihtaa vielä alatukivarren puslat...

While waiting for parts, I started to clean up front part of the frame to get it ready for zinc painting.Rungon kiillotusta ajan kuluksi

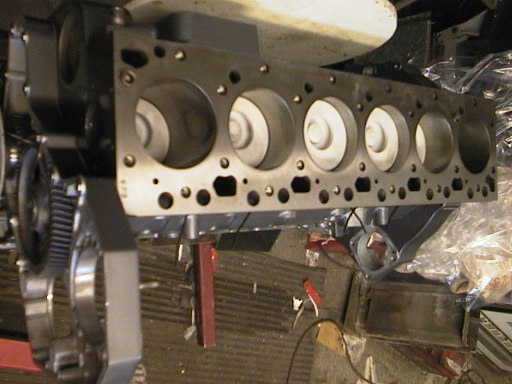

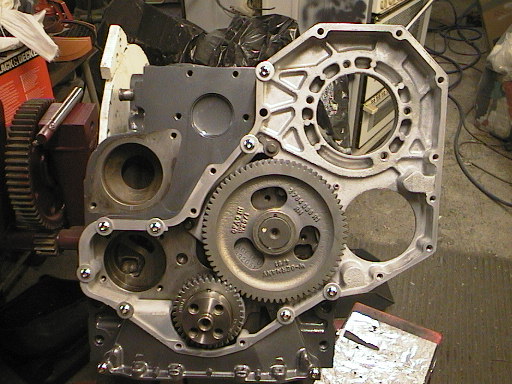

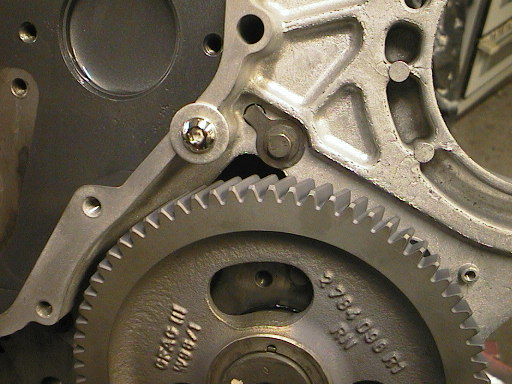

got the cam and related stuff bolted on, also KDP is fixed.Killer dowel pin- eli kotelon tappaja-ohjainpinnin kiinnitys

Engine covers painted, looking factory-stock...

Engine covers after sanding down the sprayed filler, to smooth out small imperfections.Jakopään kotelon käsittelyä

March 05

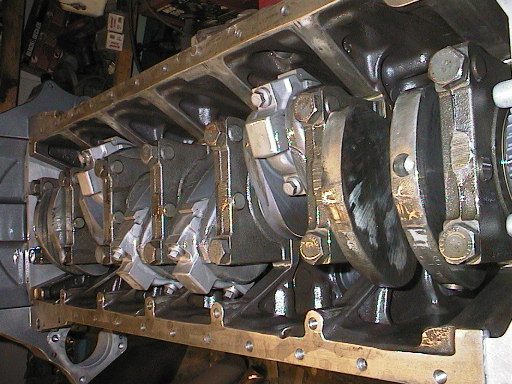

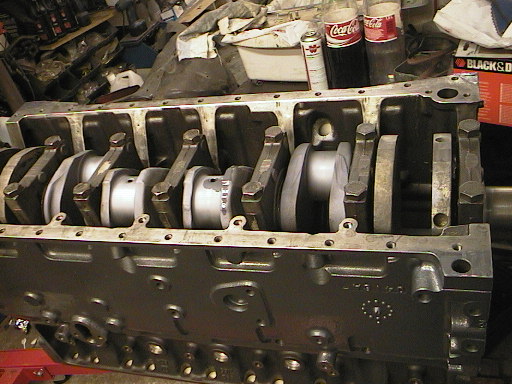

Yes! first big part is in.koneen kasaus alkanut!

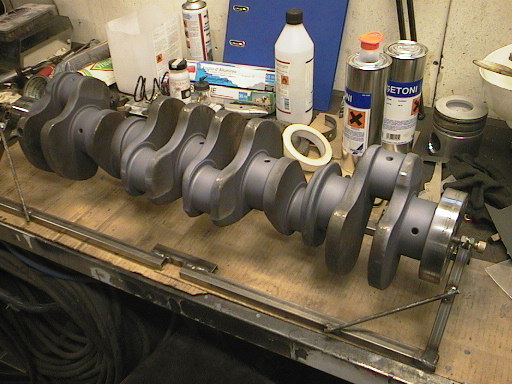

Cam and crank are now coated with DFL1, polished and top coated with WSX. In a pic is also my extended oven set up, with digital temp.gauges.

How to place XL-long crank on owen? place another old owen opposite to it, cut the backwall out; Low-tech is cheap! ...it heats up the garage nicely at the same time. No worries about haard winter temps outside.Kampura ja nokka-akseli käsitelty DFL-aineella, ja lämmitetty itse-väsätyssä limousine mallisessa uunissa...

Crankstand

CamstandHow to spend Saturday perfectly;send wife and kids to visit relatives and lock yourself to garage!(well that was a accident...) What you are looking at 2 pics above is around nine hours straight job, first I made stands for cam and crank, then wash them with acetone, after that blasting with aluminum oxide, then acetone wash again, after that pre heat them in a oven to 122F, then I sprayed coating and then back to the oven, 300F for one hour.Pic is taken just before putting it in.

Coated the pump gear yesterday with DFL1 and it turned out to be ok, needless to say which one is coated..Pumpun ratas käsitelty DFL1:llä, eron huomaa käsittelemättömään verrattuna

February 05

All pistons are now top coated with CBC1 and sides with DFL1, I puffed the WSX for the wrist pins and for the pin hole, then lightly polished the sides of the pistons with 1200 grit paper and will do the same for the top parts as well.kaikkien mäntien laet käsitelty, ja sivut hiottu 1200 h-paperilla

Practiced coating for an old piston, first try was too thick layer and it started to bubble off during baking, I blow it off and tried again with thinner layer and it turned out to be ok, pic is taken after oven treatment.Käsittelyn harjoitusta vanhalla männällä

Rod bearings after coating with DFL-1 and baking them one hour in 300F.Työntötankojen laakerit käsitelty DFL-1 aineella ja uunin lämpöön

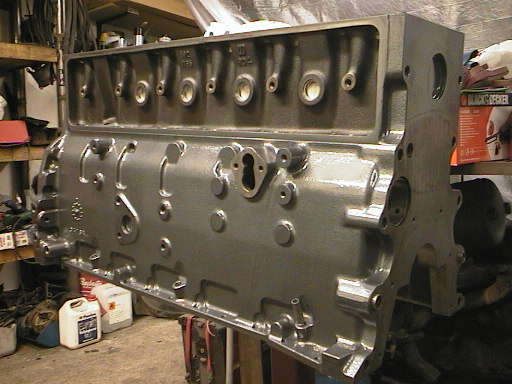

Block painted:

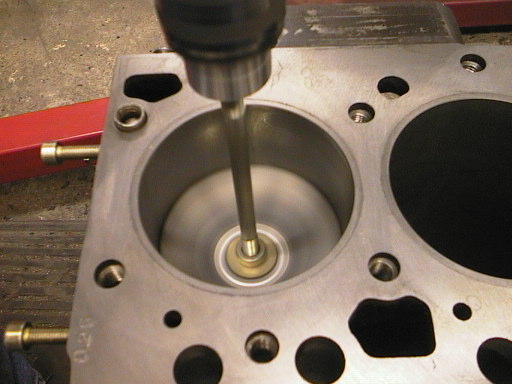

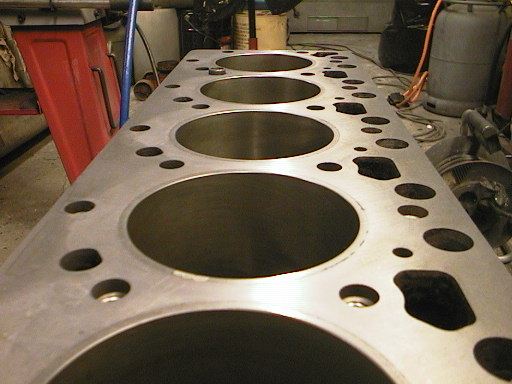

got the cylinders done last evening with http://www.techlinecoatings.com/Engine.htm,that reduces friction, it simply buffed on with cotton disk, same thing will be done for lifter bores,crank,valve guides,lifters and wrist pins too. Funny stuff, It's black powder but ones puffed on it turns cylinders slightly yellow, although it's difficult to see in a pic. Sylinterit päällysetty WSX-pinnoitteella, aine vähentää kitkaa,katso linkistä lisätietoja.

January 05

Second layer of noise insulation is partly done (LA20MA), the area next to ac evaporator is going to be covered with LA7GFPV, like mentioned before. I changed the plans bit and use LA7.... only on the areas close to turbo and exhaust manifold, since it's noise dampening capacity is not so great as the other material but it can withstand temperatures around 600C/1100F.

Got the last pieces of bitumen on their places yesterday evening.

Bitumen's are done and it's time to add other layer of noise insulation material, which would be LA20MA for the firewall and behind the engine LA7GFPV. http://www.noisetek.fi/noise.htm

Got the other one done today, now both are painted in body color of SuburbanLokasuoja maalattu korin väriin

Now the 2mm bitumen is also added inside of the heater box too, don't know how much it will reduce noise but it can't hurt either. On the fenders, I used paint removed to took of the paint from that area which is now primed with gray colored zinc paint, it contains 96% zinc and should offer really good protection against rust etc. although the fenders are already zinc coated but extra protection on fenders "dirt" side will further help against rust. Check the Zinga page Zingacoating.comLokasuojien alareunoihin sinkkimaali ruostumisen ehkäisemiseksi

The fenders are grinded ready for paint and during weekend I'm going to spray them for same color as a body of burban.

The heat shield is done, going to replace the screws tomorrow with better looking stainless hexagon screws. Holy mothers that shine...!

Raw material and finished "product".

Took of the heater/ac case in order to clean it up, I'm going to add some bitumen inside of the case, since it's hard plastic and works as a echo box. I also need to make a heat shield for the end which is closes to turbo and removing the whole case eases up the work. I started to make the heat shield yesterday evening and it should be ready today, will add some pics of it tomorrow. Also added 2mm bitumen to the "intake" area of fresh air, for further help to reduce noise.Ilmastoinnin kennon lämpösuojan väsäämistä turbon hehkumisen vuoksi