December 04Started to put 4mm "bitumen carpet" for the engine bay, to keep the structure-borne noise level low as possible.Eristysmaton asennusta

November 04

Got the exhaust pipe done with the last details last evening and spend the rest of the evening for doing the tip for it. It turned out to be a pretty nice, or what ya think... I know the mud flap, it's looking bad but I'm going to replace them later. Pakoputken pään tekoa, roiskeläpät tulevat vaihtumaan

Looks great, lurking behind the wheel...

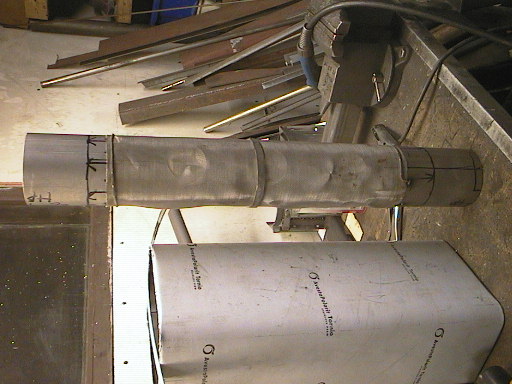

In the pic is everything except downpipe and rear part is spot welded together but got it all welded last evening and added missing hangers. All it needs, is to bolt it on ones more and double check everything, add a few minor things, like exhaust tip and last hanger just next to rear wheel. Then it's time get it sand blasted to get a nice and clean surface for it. Kuvassa on kaikki paitsi alasmenevä putki

October 04

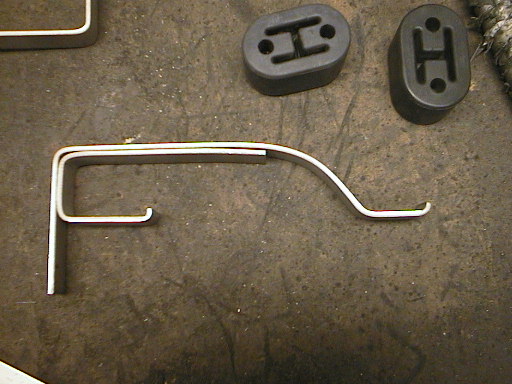

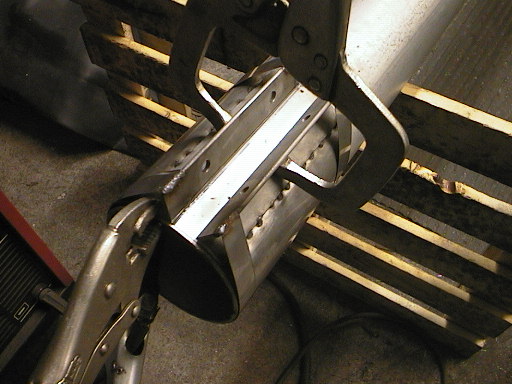

Got first exhaust pipe hanger parts done, except weldings and bolt holes

The donwpipe is done and bolted on place, so is piece of tube from downpipe to the muffler. Next I'll do fasteners for the front part before going over the rear axle.

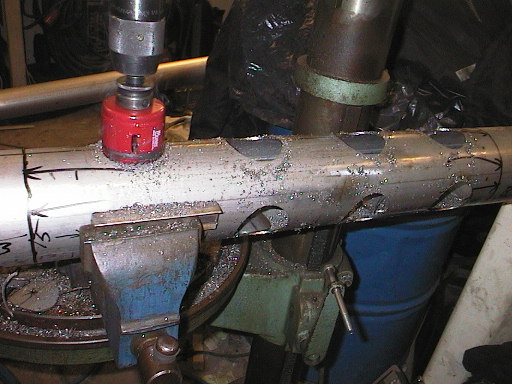

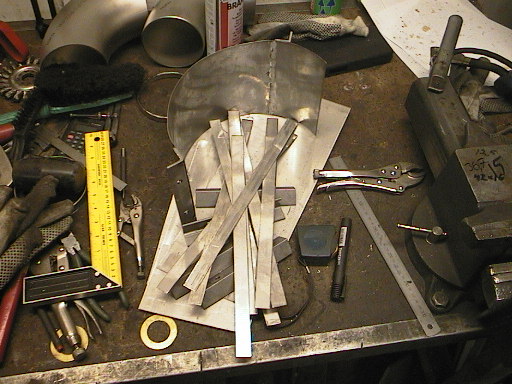

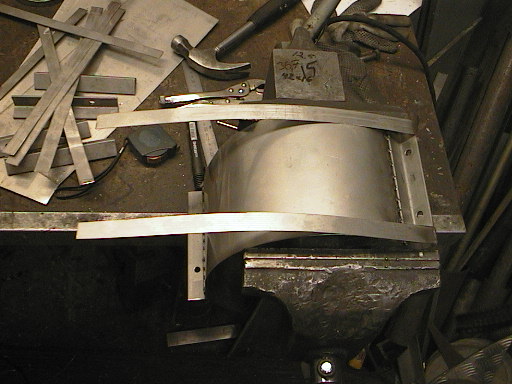

Making of a muffler. First I drilled 60mm holes for it and then bended the outer shell for it's shape by using simply piece of tube and clamps

(0.8mm stainless steel) then added a tight stainless mesh around the center tube to prevent the rock wool blow out with the exhaust gasses.

next insert the wool inside of it and put the tube in, weld it all together, remove protective plastics and you got a true flow through muffler.

Last night I made few exhaust clamp's, been using similar clamp's on my Turbo Diesel Buick and in my Jeep, they have been proven to work well, although it's a little extra work compared to ready ones from a shop's. But they don't smash the pipe while still left the joint a bit flexible and disassembly etc. things what you may want to done for the pipe later on is a breeze, since everything is stainless, just bolt it open.

September 04First piece of down pipe on it's place.

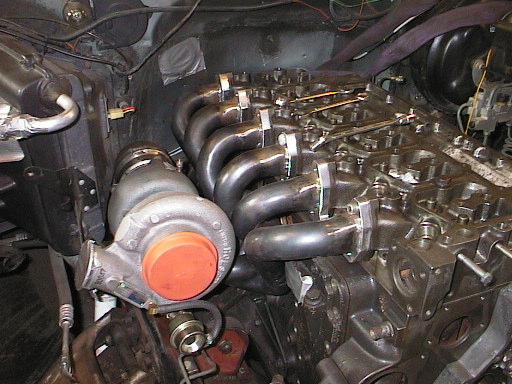

Got the adapter between turbo and the 4" stainless down pipe, next weeks are going be spent with the exhaust pipe work.

August0431st:Some welding joints grinded smooth and it started to look quite nice, although it still needs lots of work, around evenings of a week or so...

29th:Got the exhaust manifold spot welded together(cylinders 4,5 and 6), next thing is to finish the weldings and deburr it all over to make it nice and clean.

Few tubes spot welded on their places, it finally starts to look alike header.Again; unique products from garage-factory

Correct oneFirst attempt to do a collector of notched tubes, which turn out to be a bad design due to lack of space what I had before turbo, well, it had been too easy and clean anyway, so I picked up an old and faithful die grinder and handful of 90 degrees elbows and after some sparks, they seem to sit there quite well, although this is just a start, they still need plenty of grinding. So watch out neighbors there's a great chance for local "spark showers"

A miss