December 03Intake valve with 30 degrees back cut where all the edges are smoothed out, it also made a nice swirl pattern for it.

Also the exhaust valves had a back cut and I radius the front face to margin area to help the low lift flow.

All the edges are smoothed out from the combustion side of the head to further help the flow and prevent hot spots.

Got the head and valves back from a shop and spent yesterday evening by finishing all the sharp edges off from a fresh valve seat job. Valves are with 30 degrees back cut, I may touch then lightly for later on to smooth out the 30 degree angle, will see that...

November 03

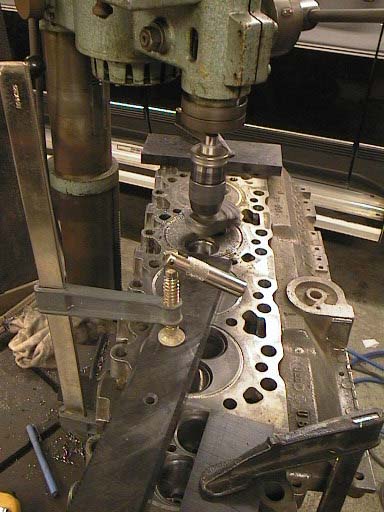

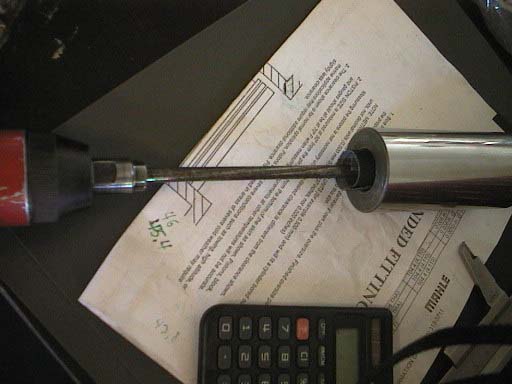

Since my machinist can't do the job, I was forced to cut the grooves by myself. Here's my $20 O-ring tool, I buy a cutoff tool for a lathe and weld about 1" piece of it to a chunk of steel, then drilled a hole for center bolt. I used old gasket marks as a temp plate and cut the grooves 1mm deep and 1.5mm wide. I'm going to take the head for milled to be sure it's straight and cut the grooves deeper after that if needed.

Sept.03

When comparing new (FelPro) and old head gasket you could clearly see how narrow the fire rings are on the FelPro, also the seal stripes are single line design in FelPro. Email to PDR clear up this issue, original Cummins gasket is the only way to go. So FelPro is for Sale.....

Aug.03

Exhaust runners are done but intake runners need a bit more polishing to be equal with exhaust side. Also the intake plenum area needs to be finished, thus looks like I'm going to let the grinder scream a few more weeks.

July03

Balancing the pistons, now they all are 1964,5 grams with the pin and rings.

Note that the piston on scale is NOT yet balanced...

I "honed" the pins with roll of sandpaper to get the piston weights even

Measuring the piston chamber, all turn out to be equal 44 cc.

Finally got the rods polished! Took more than a weekend.

The block and crank are back from shop. Block is sleeved, bored, honed and line honed. Crank is grinded and polished. Next thing to do is measure the piston protrusion and took the block back to the shop for final shaveBeam polishing the rods

See the difference? nice nice shine shine...

but wait, its not ready yet- so dont prejudge my work!

check for updated

pictures from the sub arrival...