20.3.2003

Next thing to do is a deburr all the edges of the block.

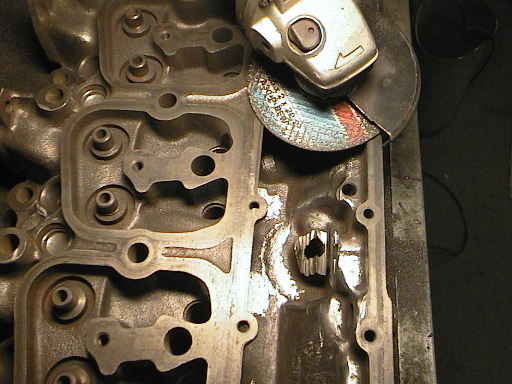

The last hump is grinded off to get a better flow to #1 cylinder"

7.3.2003

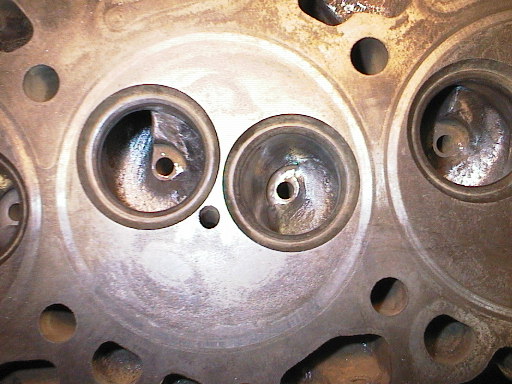

The intake after grinding down the hump, note; the hole that came visible is for the dieselfuelfilter, but no worries- it got threads so it can be "sealed".

Next target to grind down...

6.3.2003 grinding and grinding

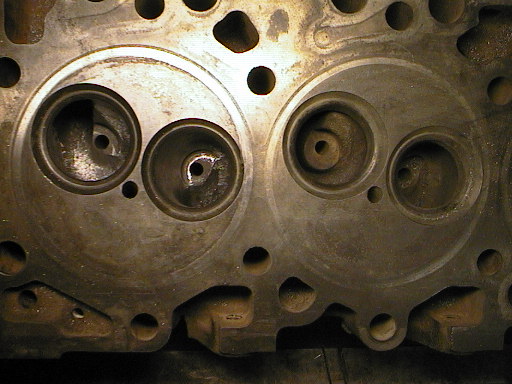

Runners grinded, next step is to polish them.

Exhaust runners ported by using an old exhaust gasket as a template-no more gasket edges slowing the fumes! I also smooth out all the sharp edges on the head, like surroundings of the injector base

While polishing the intake are I decided to cut down the "hump"-lower the hill

It's time to use more brutal tools for rough grinding!

18.2.03 flowbench development; "lowtech-hitek" hotrodding!

Note the use of vacuum cleaner!Make a big U from clear hose fill it halfway with water, connect the other end to your vacuum cleaner hose. The usage, turn the vacuum cleaner on, mark the water level to the hose, put the vacuum cleaner hose to e.g. ported intake runner, mark the water level, then switch to the unported intake runner, mark the water level. You are going to see the difference in water column between unported and ported runner, so no numbers of flow, just the direction, good or bad porting job...

crank and head polished 11.2.2003

ALRIGHT CRANKS, BATHTIME!

NOW CLEAN AND DRYING

ONE DONE, FIVE TO GO...

HEAD UNDER WORK3.2.2003

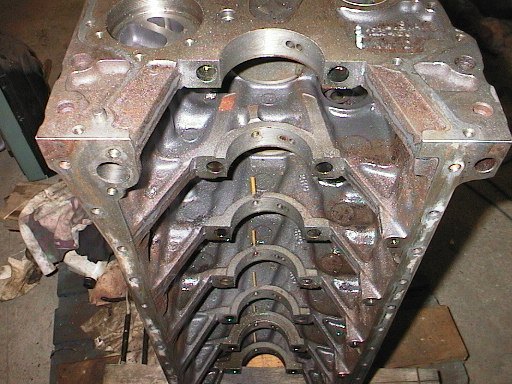

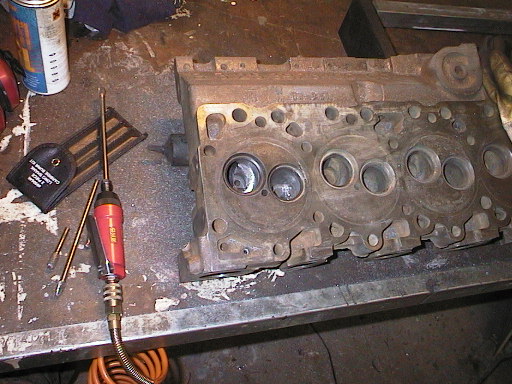

Cummins block is torn down!-so totally that even pics flip! sorry ībout that!

pistons in line

little baby is rocking in order to fell a sleep?- the crankshaft was unbelievable heavy! made for heavy-duty use, yeah thats ok.